Dual boilers have been integral for La Marzocco espresso machines ever since the launch of the La Marzocco GS in 1970. By separate the brew boiler from the steam boiler, Giuseppe Bambi was able to create a near endless amount of steam pressure while maintaining brew temperatures in the ideal range. Giuseppe’s original design also included saturated group heads, where water from the boiler constantly ciruclates around the portafilter, maintaining a temperature equillibrium that is energy efficient. This design is still standard in modern La Marzocco espresso machines. We recently asked Niccolò Frosini, La Marzocco’s Technical R&D Manager, about the significance of dual boilers in espresso machines.

How has the design of the saturated group head changed since it was introduced in 1970?

The concept of the saturated group has remained largely consistent since the 1970s. However, we have continuously worked — and still do — to keep it at the forefront of technological innovation in the field of coffee machines.

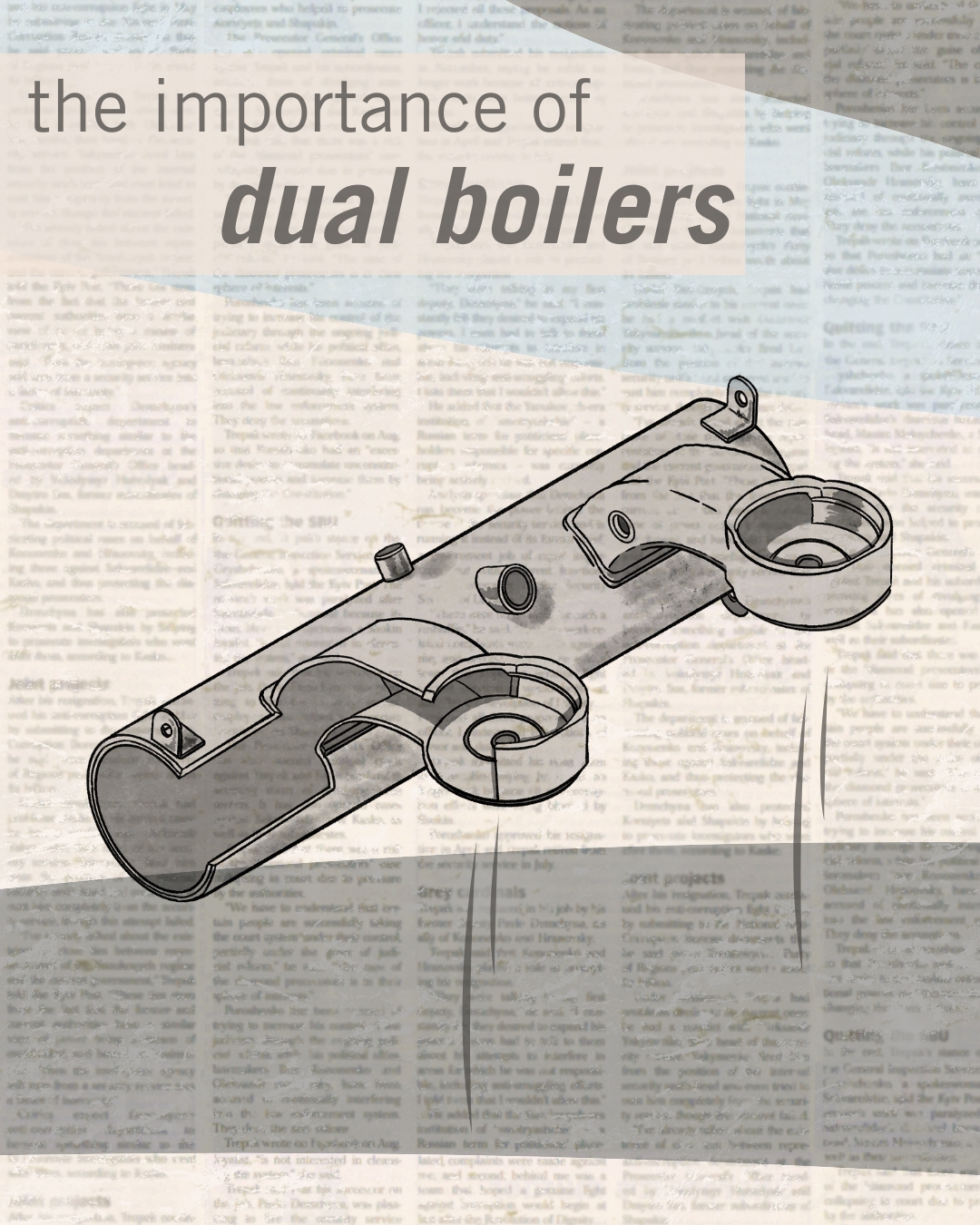

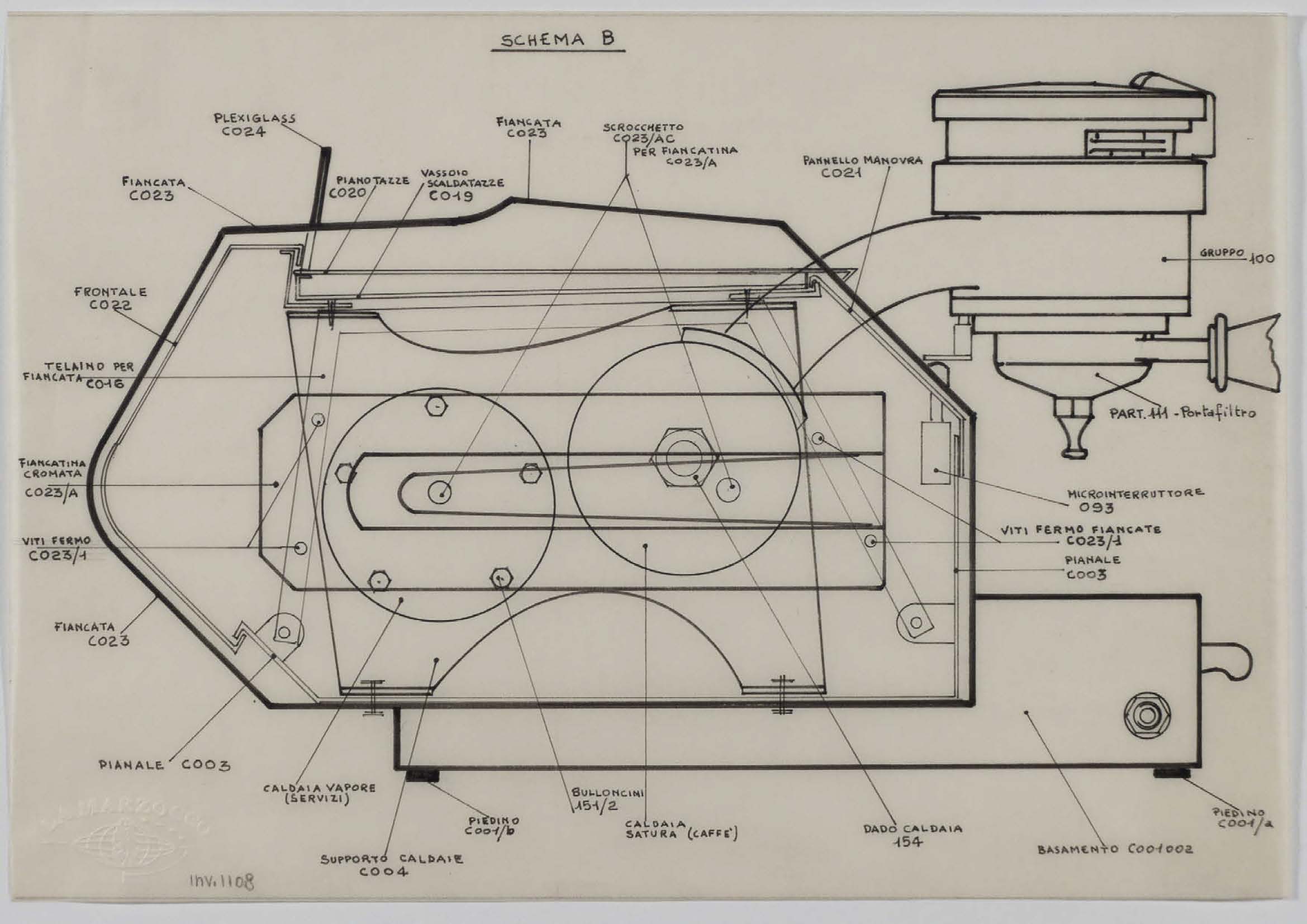

Initially, due to the limitations of available technologies and manufacturing costs, the saturated group was composed of four separate components: the boiler cylinder, the group head, and two end caps. These were held together using bolts and nuts, with a gasket required to ensure a proper seal. As a result, maintenance was frequent and often necessary.

As technology advanced, we moved towards welding the boiler into a single, unified component. This transition was far from simple; it required extensive research into welding techniques, durability over time, and reliability in operation. Eventually, we introduced robotic welding for the coffee boiler, a significant step forward that ensured both high performance and increased consistency.

A major shift in our approach came with the introduction of the Linea Mini. Instead of using two similar cylindrical boilers, we leveraged our technical knowledge to design a boiler tailored specifically for optimal performance and a more sustainable production process. This evolution continued with the launch of the Linea Micra, which features our most advanced and highly engineered saturated boiler to date.

As technology continues to evolve and market demands shift, we remain committed to researching and developing new ways to make saturated groups as functional, efficient, and reliable as possible.

What is the main advantage of a separate steam boiler compared to a heat exchanger machine with a single boiler?

The primary technical advantage of a dual boiler system is the independent thermal stability and precise temperature control it provides for each function. In this configuration, the brew boiler operates at a stable temperature optimized for espresso extraction, while the steam boiler runs at a much higher temperature and pressure to generate dry and powerful steam.

In contrast, a heat exchanger machine uses a single boiler maintained at steam temperature. Brew water is drawn indirectly via a heat exchange tube that runs through the boiler. While this allows simultaneous steaming and brewing, it introduces a level of thermal inconsistency—since the brew water is flash-heated, its temperature is indirectly influenced by boiler pressure and requires a cooling flush to stabilize before each shot.

Dual boiler system decouples brewing and steaming thermodynamics entirely, offering more predictable extraction temperatures, reduced recovery times, and improved control over brewing variables, which is critical for achieving consistency in specialty coffee preparation.

What is the main advantage of individual group head boilers on the KB90, Strada S, and Strada X compared to a shared group head boiler like the Linea PB and GB5?

Every time we use single boilers on professional coffee machines, we do it to give the barista more room to “play” with the machine. The advantage of having single boiler for each group is that you can have different temperature and pressure on each group. Independent pressure regulation can only be achieved with gear pump (only Strada X has it). This is necessary to make sure that every kind of coffee used in a coffee shop can have its own recipe and can be brewed accordingly to what the barista thinks is the best. Maximum control.

Another great advantage of having individual boiler is from an ecological point of view: Each boiler can be turned off individually to minimize energy waste. This feature can be used in situation where the workflow slow down for example.

What is the most important thing people should know about having a dual boiler espresso machine with saturated group heads?

The most important aspect to understand about a dual boiler with saturated group heads is the unparalleled thermal stability and consistency it offers during extraction. As per before, in this configuration, the brew boiler maintains a precise, independently controlled temperature and it ensures minimal temperature differential between the water leaving the boiler and the point of extraction. This design virtually eliminates heat loss and thermal lag, which are common in other systems. When combined with the ability to steam and brew simultaneously without performance compromise, this setup becomes essential for high-end or commercial environments where precision and consistency are non-negotiable.