In the late 1960s, La Marzocco was looking to innovate. More and more research showed that water temperature significantly affected the flavor quality of espresso, but the predominant design for most espresso manufacturers was a heat exchange system. In a heat exchange system, the cold water drawn into the machine is heated by the water lines wrapped around or run through the larger steam boiler. This means that when the café is busy, the water in the brewing lines is replaced too quickly, leading to a dramatic drop in brew temperature. If the machine is idle for too long, the water in the brewing lines starts to boil.

To compound these issues, the average cup size in America was still much bigger than Italy’s five- or six-ounce cappuccino cup. That meant American coffee bars had to turn the temperature of their espresso machine’s steam boilers higher to meet the milk steaming demand, further exacerbating the overheating issues with heat exchange machines.

Giuseppe Bambi, one of La Marzocco’s founders and the company’s leading espresso machine designer, had already experimented with the idea of multiple boilers with the La Marzocco Poker starting in 1964. In the Poker, the second boiler used steam to inflate Teflon bladders that drove the piston, bridging the gap between lever machines and electronic pumps that would come soon after. But the use of dual boilers gave Giuseppe an idea.

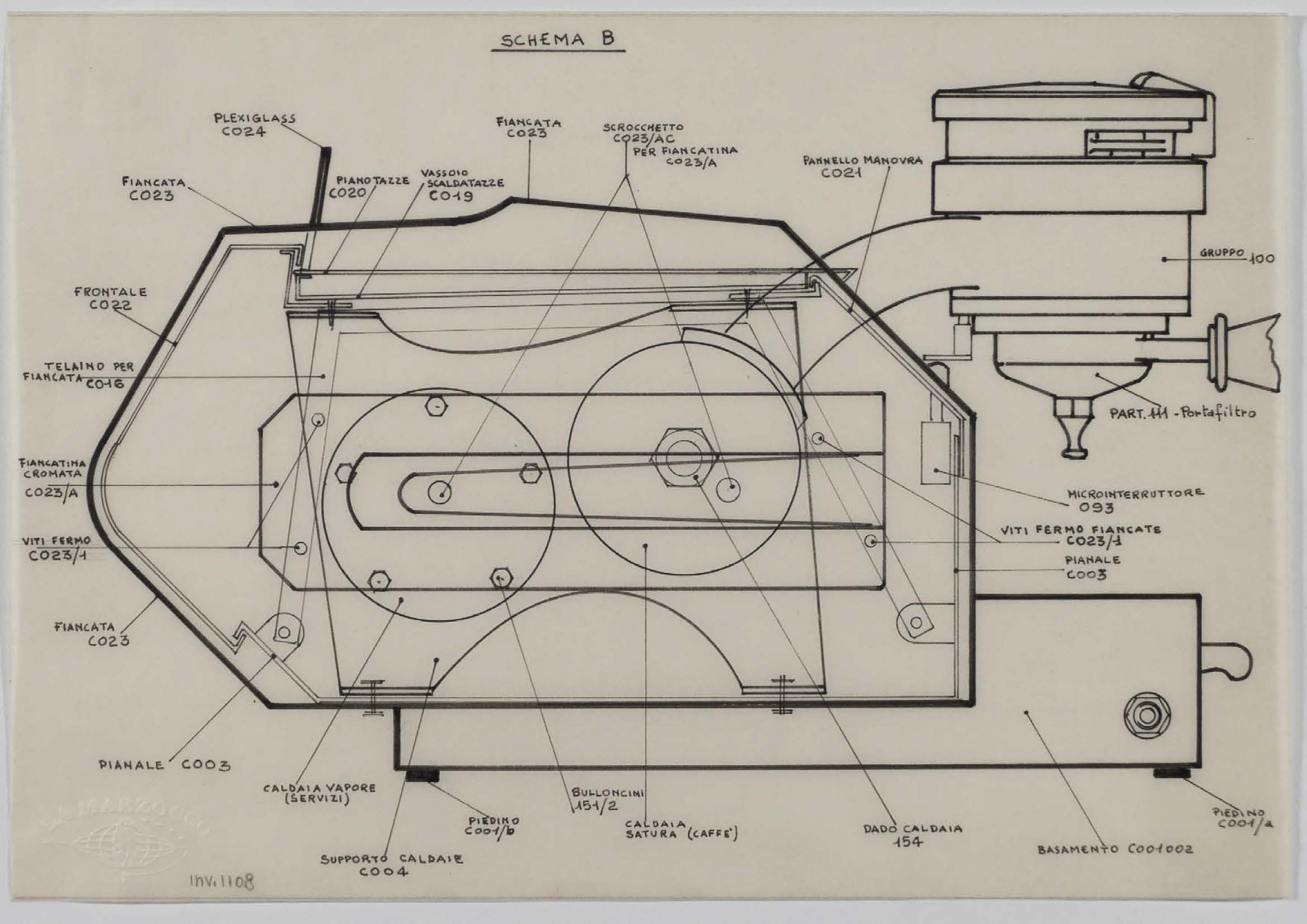

In Italy, steam boilers over five liters needed to be inspected by a government regulatory body. This could add weeks to a production schedule, and manufacturers had to pay a fee to inspect their large boilers. Smaller boilers, however, didn’t need to be certified. This flexibility led Giuseppe to start experimenting more with espresso machine design. After patenting the first horizontal espresso boiler in 1939, Giuseppe was no stranger to innovation for workflow and coffee quality. He soon realized that creating a separate brew boiler would dramatically control the water temperature better than a heat exchanger machine could. While the thermometer inside the standalone brew boiler would still see some temperature swings, it would never reach a boil and therefore never overheat the coffee during brewing.

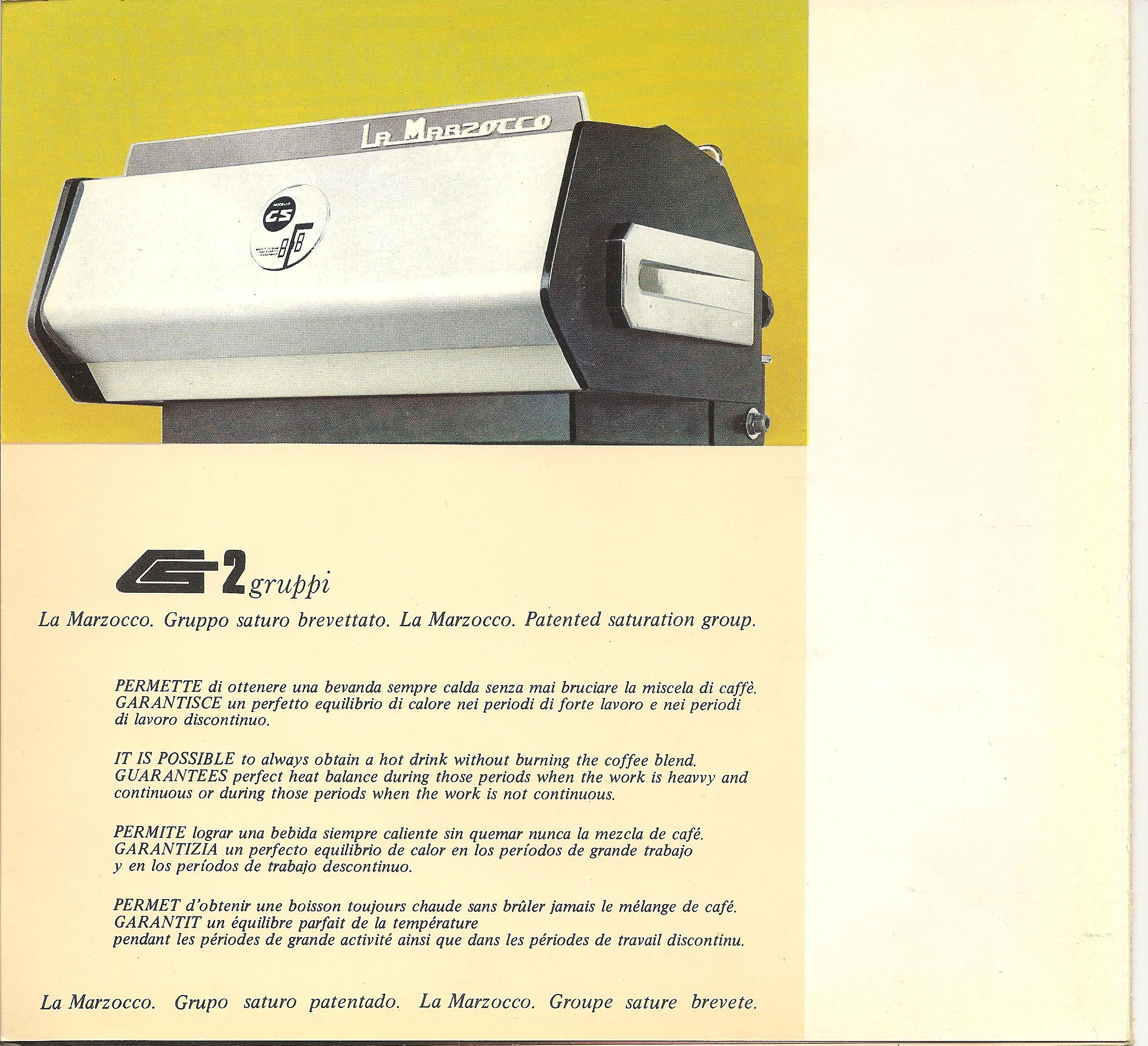

With that idea, Giuseppe wanted to stabilize the temperature even further. Many manufacturers used brass dispersion blocks in their group heads to act as a heat sink for better temperature stability, but for Giuseppe, this wasn’t consistent enough. Instead, he welded the group heads directly onto the boiler, slanted at an upward angle, so that the warm water would continuously flow up and around the group at all times. He called this new design the saturated group head, and it was what gave his latest espresso machine its name.

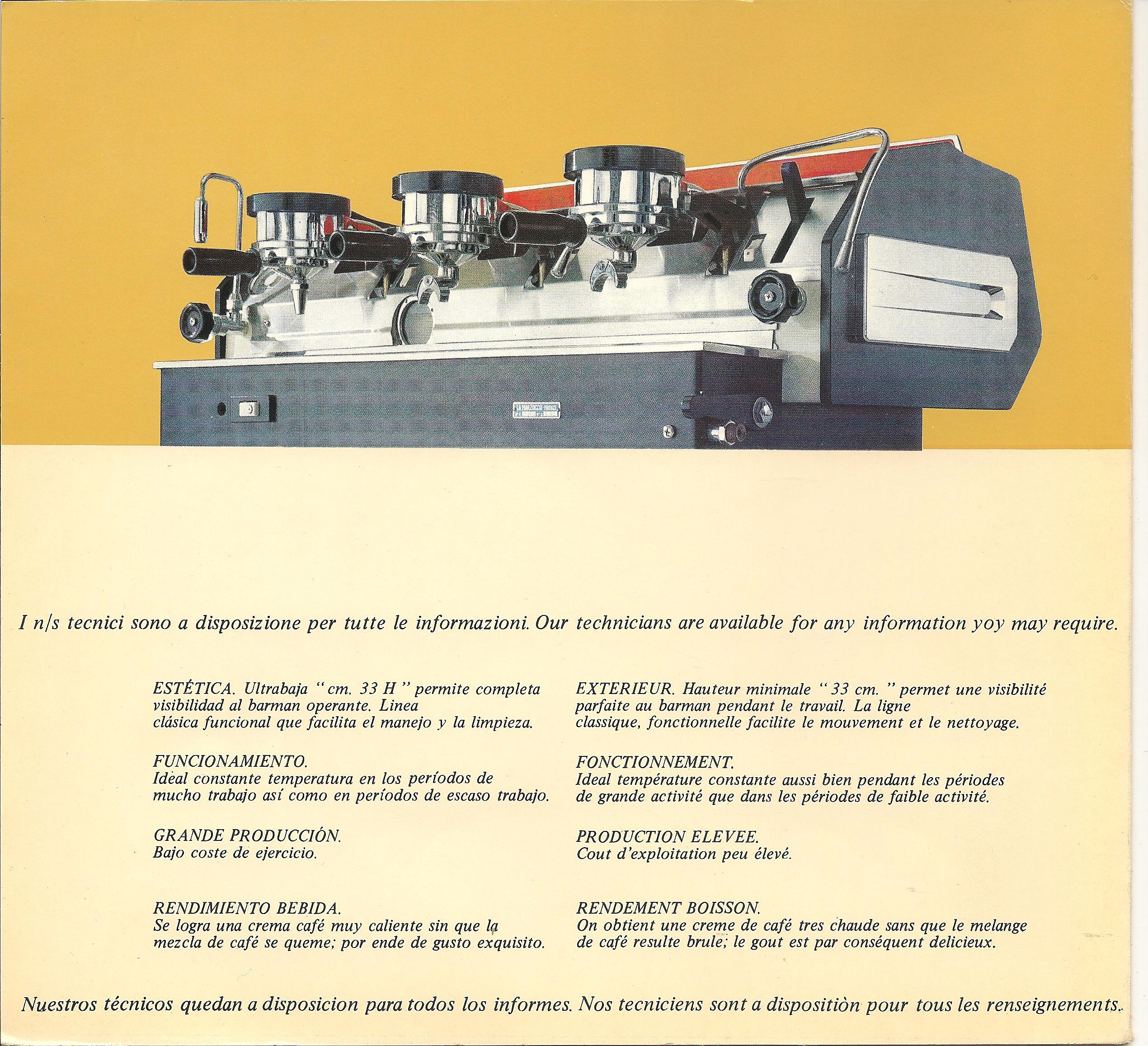

In 1970, La Marzocco debuted the GS, which stood for “gruppo saturo.” It was immediately successful in Tuscany, and you can still find some original GS models in old-fashioned public houses called Casa del Popolothroughout the region. However, there was one other region where the GS started gaining popularity: Seattle.

Before La Marzocco had a US branch, Kent Bakke and his team imported restaurant equipment to service Seattle’s growing food and beverage industry in the 1970s. However, their first La Marzocco GS changed the entire direction of the Italian company. The results were drastic once it was set up in the small office in the United States: no other espresso machine could pull a shot that tasted this good. The proof was available for anyone to taste: the La Marzocco GS made the best espresso in the world.

As Kent and his team kept importing more and more La Marzocco GS espresso machines, Italy began to take notice. Soon, La Marzocco had an official branch in the United States, and machine design was improved to meet a growing audience worldwide. The GS2 added new features like an automatic brew timer and, later, a mechanical flow meter for volumetric espresso. Another advantage to the dual boiler design of the GS and the GS2 was that flow meters in heat exchange machines would measure cold water as it entered the espresso machine, affecting accuracy as the water was heated. The GS placed the flow meter near the group head, where it would measure hot water and deliver better consistency than the competition.

Throughout the 1980s, the GS2 was a popular machine for people who wanted top-tier espresso quality and weren’t willing to compromise. The factory made a version with a slightly larger steam boiler for American cafés. While the GS helped establish La Marzocco as an espresso machine manufacturer with worldwide appeal, the partnership with the US-based office helped give critical feedback on what cafés outside of Italy were looking for in an espresso machine. As a company, La Marzocco greatly appreciated input from baristas, who made coffee every day and used their machines more than anyone else.

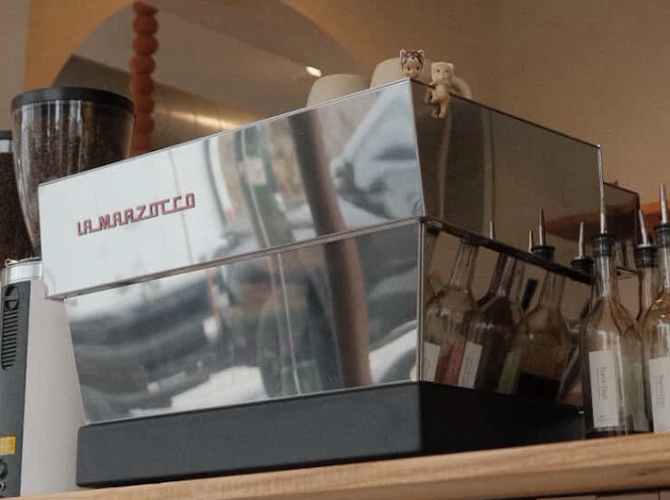

Even though the technology was first launched in 1970, the dual boiler espresso machine with saturated group heads is still integral to every modern La Marzocco espresso machine, with only a few changes made to the initial design over the years. The original GS paved the way for the La Marzocco Linea, the first machine Giuseppe’s son Piero Bambi designed for the company from the ground up. Building on his father’s saturated group head and dual boiler design, Piero created the Linea in 1987 to help meet the demand of busy espresso bars without sacrificing espresso quality or steam power.

With the Linea modernizing La Marzocco’s espresso machine lineup and setting the stage for the explosion of specialty coffee in American in the 1990s, it’s safe to say that the La Marzocco GS completely revolutionized espresso preparation. And even though Giuseppe was thinking about temperature stability from the start, the legacy of the machine was rooted in his clever dual-boiler innovation that allowed La Marzocco to experiment more with design while avoiding the slowdown of the certification process—cementing La Marzocco’s dedication to workflow both on the production floor and the coffee bar.

Special thanks to Camilla Catarzi and Tim O’Connor for their help with this article.