Opening Notes is a new content series from La Marzocco focusing on the information everyone should know before they open their first café. Over the next few months, this series will examine topics that cover business practices, marketing ideas, and café operations, each featuring a coffee expert in that field.

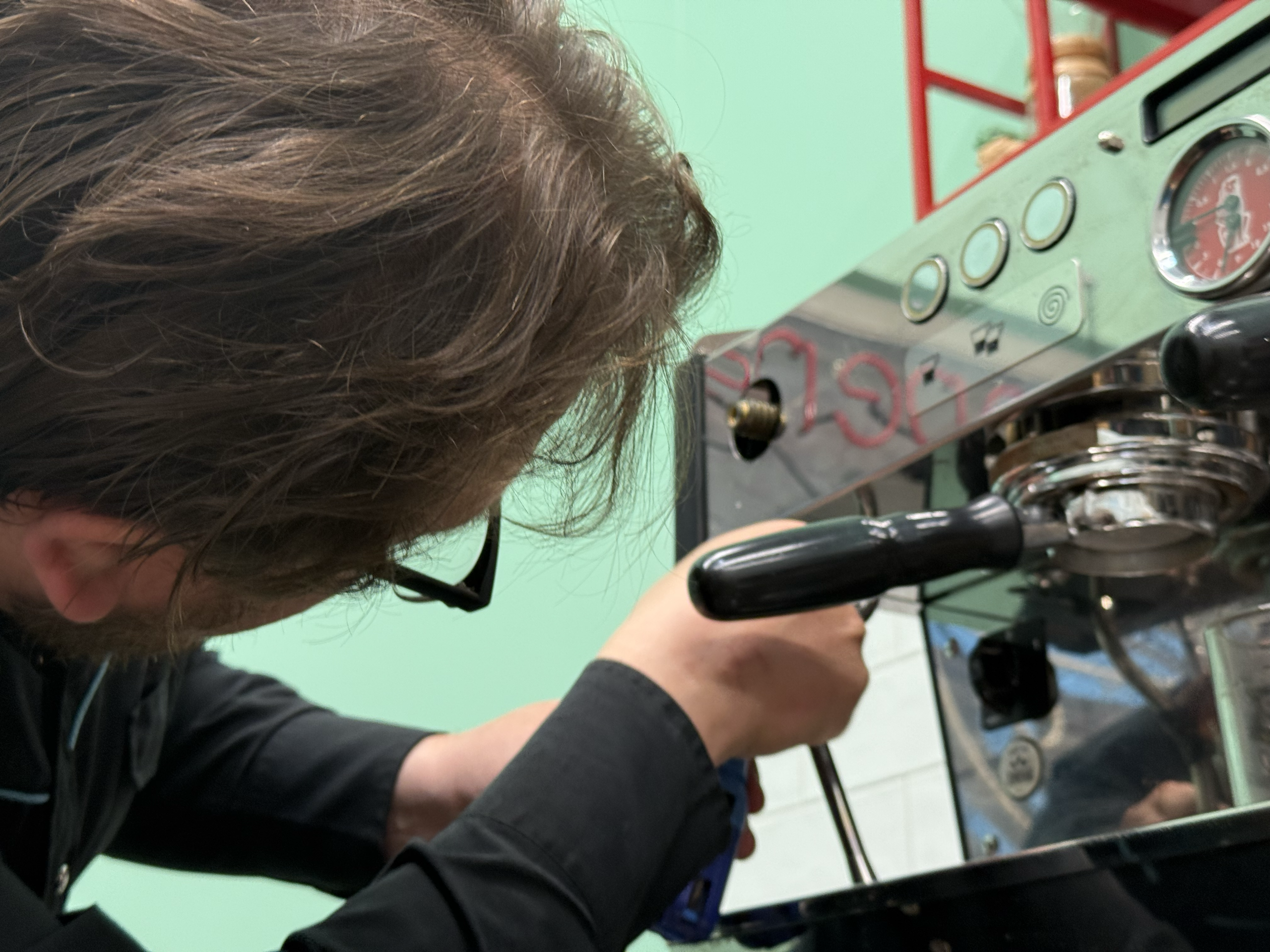

Jackson O’Brien is the Coffee Ambassador for Peace Coffee in Minneapolis, Minnesota, where his role is to help wholesale customers achieve great success. That means he does a bit of everything—customer support, education and training, and most importantly, machine installation and espresso maintenance. He’s also a longtime United States Barista Championship judge, with over 20 years of experience working in specialty coffee in every role from barista to trainer to quality control. We spoke with Jackson about how to prepare a café space for equipment installation and how to maintain that equipment for years to come.

What’s the most important thing people should consider when planning for an equipment installation?

Over-communicate with your install tech about the power, water, and drain setup. It stinks so much for everyone involved when I show up for an install and only discover when I arrive that the power has the wrong amperage, or that the water isn’t turned on, or that there’s a drain nearby but no hole cut in the counter to route it. Take photos of the space, and if you have any questions about what the installer requires, ask those questions. It’s way better for you to ask “how can I tell if the compression fitting is ⅜ inches?” than assuming it’ll be fine when it isn’t and delaying your installation for a week.

What other things should people keep in mind to prepare their space for espresso equipment?

Remember that the space where you’re installing your espresso equipment isn’t like installing a furnace or something. People need to interact with it; they need to have room around the machine to work and set cups, pitchers, syrup bottles, and hand those finished drinks off. I’ve encountered more than one person who has found out that the espresso machine they wanted was 28 inches long and 23 inches deep, and so they got a table that was exactly big enough to fit it and nothing else to put it on. One time, I ended up needing to put their grinder on another table with a hand sink between the grinder and the machine. I can’t imagine what a nightmare it is to work in that space.

How can you guarantee that your space is ready for an installation?

Having photos of the space is amazing. Having a sense of not just “there is a place to put the espresso machine” but also a sense of how it’s going to go into the building and how it’s going to be oriented with everything else lets me have a game plan before I even walk in the door. Telling the installer, “I have 220VAC 30 amp power,” is good. Including a photo of the receptacle you have installed is better. Having the NEMA code is best, but I understand that cafe owners have better things to do than learn what a NEMA code is.

Once a new machine is installed, what’s your key advice for café owners to keep it running well?

Keep it clean and change your water filters regularly. Prior to getting into machine maintenance, I was under the impression that cleaning the machine and changing the water filters was just to keep the coffee tasting good. Given that the municipal tap water where I live tastes pretty good and makes a fine cup of pourover coffee, I wasn’t too worried about changing water filters until one day I learned how to rebuild our group heads and found out that the machines’ boilers were full of rocks. Those water filters aren’t just there to make the water taste okay; they’re there to keep your machines healthy.

What is preventative maintenance?

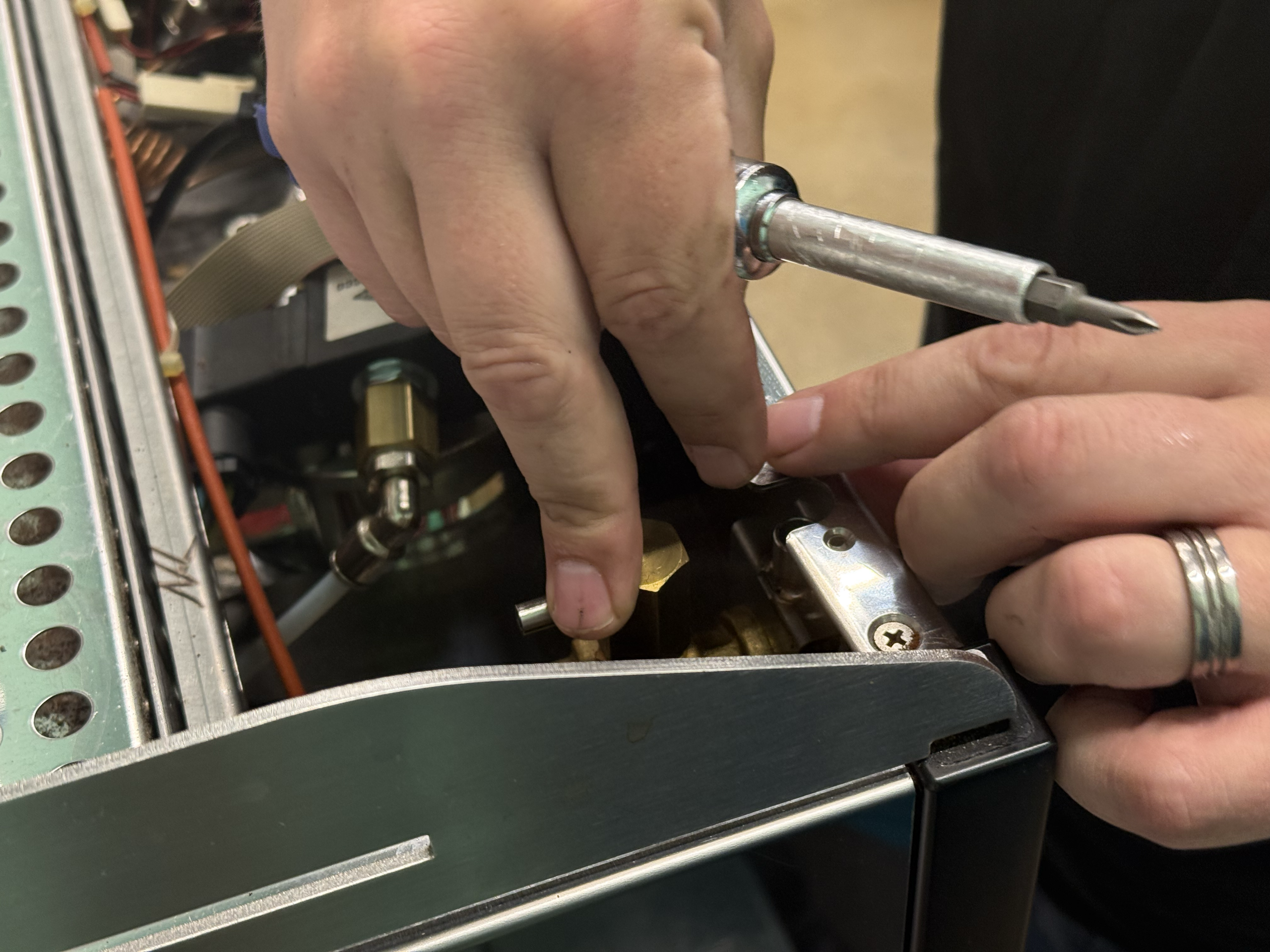

The universe is working against you while you’re keeping a giant tank of hot water at high pressure on your countertop. Eventually it will break if you just leave it alone. Just like your tires are constantly being worn down a little bit every time you take your ride anywhere there are fittings and gaskets and valves that are being worn away with every drink you build on your espresso setup, and preventative maintenance is there to replace these parts.

Why do espresso machines need preventative maintenance?

You want to perform regular preventative maintenance tasks because these parts are going to fail due to regular use over time. Preventive maintenance is there to replace or repair those parts just before they break, so you never actually encounter any downtime. Also, when you perform a preventative maintenance task, you can schedule it to happen at a time of your choosing that works best for you and your employees. Wouldn’t you rather have your machine be down for half an hour at 3:00 PM on a Wednesday because you scheduled a steam valve rebuild rather than have the machine be down for half an hour at 9:00 AM on a Saturday because you needed to call a tech in for emergency service because your steam valve broke?

What are some preventative maintenance items that café owners can perform?

As I said before, keeping the machine clean and keeping the water filters changed is a huge starting point for preventing your machine from breaking, and 100% counts as preventative maintenance. Café owners also can and should replace their own group gaskets and dispersion screens. Every time I have to charge someone to do that, I feel bad for taking their money. An underrated part of preventative maintenance is also just confirming the proper operation of machine components. If you’ve got an espresso machine with volumetrics, check its brew weights once a week and make sure they’re still consistent. Keep an eye on those gauges and make sure they’re staying within operational ranges. Measure the flow rates out of your group heads. Knowledge is power!

What are the preventative maintenance steps that café owners should hire a tech to perform?

If a shop owner is handy with a wrench and understands how to safely do so, I’d say they could replace their own vacuum breakers and safety valves without much fuss, but I’ll also say that it might take a novice an hour to do that, and it’ll take a tech five minutes. I’d say that cafe owners shouldn’t try to rebuild their own steam valves or group heads on MP machines unless they’re very well trained, and if you’re hiring a tech to do those anyway, you might as well have them replace your vacuum breakers and safety valves while they’re there.

What are some indicators to look for that could signify the machine needs immediate maintenance?

Obviously, if there are drips or leaks or any other signs of water existing where it shouldn’t, it’s absolutely time to call a tech in. Similarly, if any electrical components aren’t working. I’ve also encountered people who live with switches that only work after you jiggle them a little bit or indicator lights that flicker, which seem like minor annoyances but can be indications of more serious problems. Way easier to fix a minor leak that’s interfering with your electronics while it’s still minor than to come in when the minor leak has turned into a major one. Also, if anything feels loose that should be snug, it is a warning sign. Even if it works now, it may mean that some fitting is failing and should be fixed, while it’s a minor inconvenience rather than a big problem.

Is there anything else café owners should know about setting up their machine and keeping it running smoothly?

Even if they don’t ever have any intention of doing repairs themselves, café owners having a real understanding of what the machine does and how it does it can be amazingly helpful for your relationship with your tech. I’ve had people call me for service for batch brewers, saying “the pump is broken” on machines that don’t have pumps, leaving me to guess what’s wrong. Saying “the espresso doesn’t brew right” means you’re going to be paying me to prod around at your machine for half an hour before I even start the repair and fetch the right parts and tools. Saying “the Linea PB’s flow rate on the left group is 50 ml per 30 seconds and on the right group it’s 250 ml per 30 seconds” means I’m walking in the door with a 5 mm hex wrench, a 1.5 mm hex wrench, and a new flow restrictor and I’ll have your machine back at 100% within 15 minutes. Espresso machines are complicated beasts, but they ultimately boil down to being a very fancy and particular tool, and knowing what that tool is built for and what it’s supposed to do will make your life immeasurably better, both because you can know what’s a machine problem vs a human problem, and make those repairs go quickly and easily.

To learn more about where Jackson works, visit Peace Coffee’s website. You can also follow Jackson on his Instagram page.