With over 18 years of experience in specialty coffee equipment repairs, Ryan Baugn of Wisconsin-based Caliber Coffee has almost seen it all. We reached out to Ryan for tips on knowing what to look for when it comes to espresso machine service.

What everyday things should baristas and café owners look out for that indicate an espresso machine needs service?

There are gauges, display screens, and error codes that can indicate a lot, but before you even need to rely on the machine to give you a cue, using your innate senses can be an extremely effective tool for identifying a problem. Keep your ears open for louder-than-normal noises coming from your machine. Do you hear hissing noises when things should be quiet? Do you see a small water leak or drip under the machine? Do you hear intermittent crackling noises or whining? Does the steam knob feel loose? Look and listen, feel, and dial your senses into your machine, and if something doesn’t seem quite right, it is time to call your local coffee equipment technician.

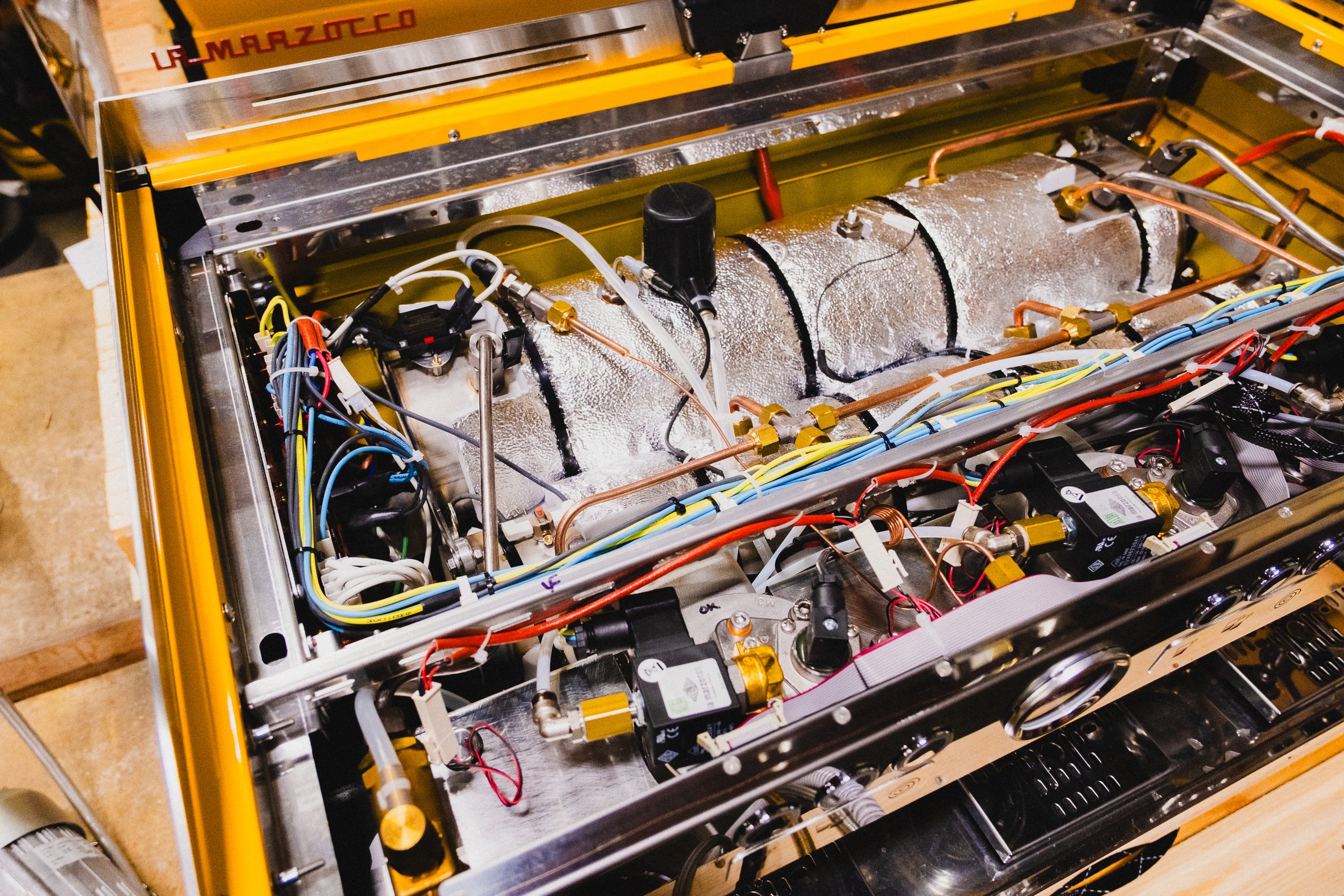

Every espresso machine has some tools and components designed to give you specific indications about the basic systems it controls. The pressure gauge(s) is the most common and essential indicator. Usually, you have a brew boiler pressure and steam boiler pressure gauge; sometimes, they are built into one component. Be sure you know your target set points; if they aren’t within range, you should call your tech. Both gauges should be clear and easy to read. The steam gauge will usually show a pressure between 1 and 1.5 bar and shouldn’t have any sudden high or low movements; they should show a gradual climb and decline to maintain a setpoint. Your brew gauge should not exceed ~12b while idle and should be a solid (no fluttering) 7b-9b (depending on your set point) while brewing. Even lower than pump pressure, post-brew pressures can indicate an issue with an expansion or 3-way brew valve.

Lastly, peek at the display screen or thermostat display if your espresso machine has one. These can give you essential warnings and codes indicating it is time to call your professional technician.

What are some more extreme warning signs that someone might notice that indicate they should shut down the espresso machine and wait for service?

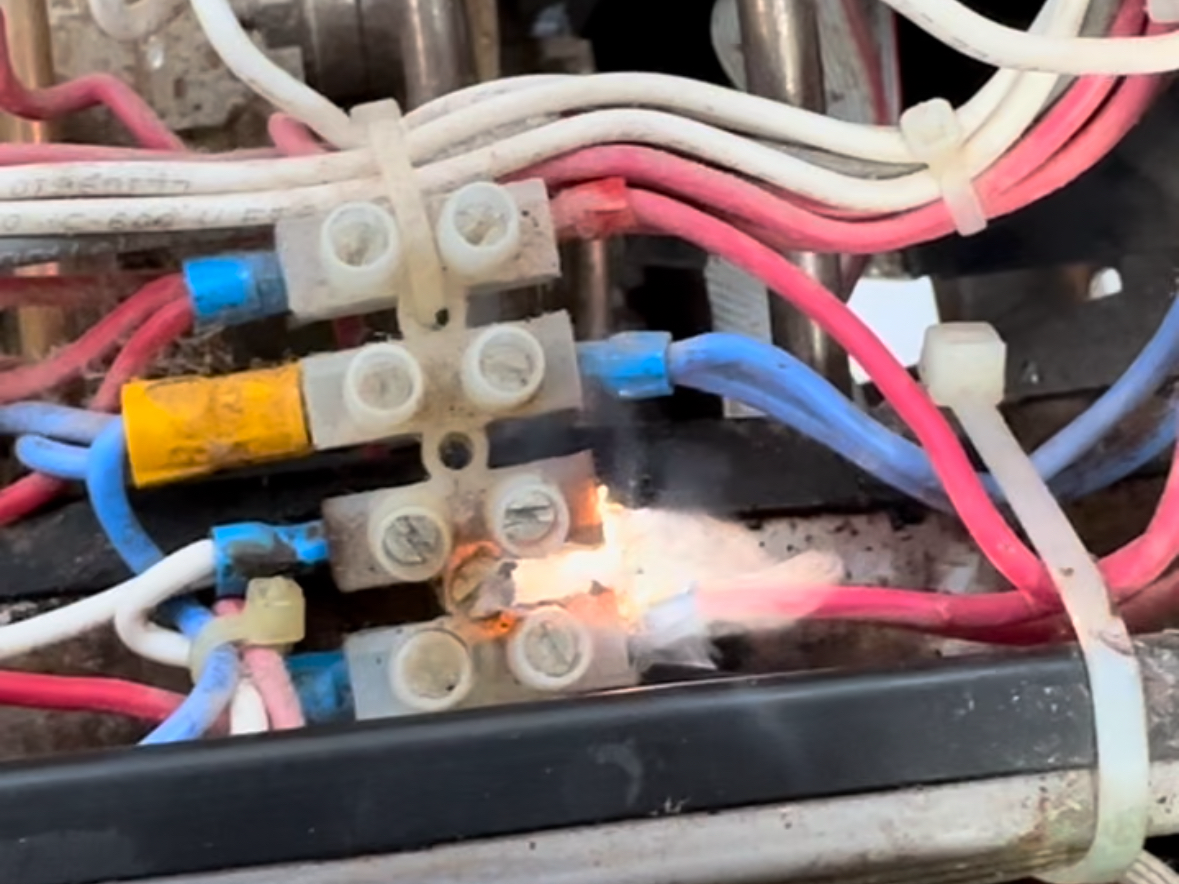

When something is going on that you can’t control, it is time to shut things down. Water won’t stop pouring out? Steam won’t stop? Know where your water supply shut-off valve is and where the electrical breaker is, and turn both off if something is happening outside your control. Eventually, if not immediately, the machine will stop. Another extreme sign would be sparking or fire/flashing from within or around the machine. This indicates that power and water should be shut off immediately, and the machine should not be used. Lastly, if a component breaks off or pushes into your machine, it’s best to shut it down until a technician can advise you on whether it is safe.

As a service provider, what are your best tips for café owners who need to schedule service for their espresso machine?

It is always better and more economical to plan ahead. Develop an ongoing relationship with a talented local coffee equipment technician before you have a problem to deal with. By investing in your machine with daily cleaning, a proactive, regular maintenance plan (executed by an equipment technician), and an appropriate water treatment system, you can avoid many emergencies. But, when those emergencies arise, you’ll have a technician who knows your business and the machine and a developed relationship they can build on to meet your needs as efficiently as possible. Too many times have I received calls from new customer coffee businesses that may have attempted to repair issues or have avoided regular maintenance. Most coffee tech companies will require a prior relationship to dispatch emergency service. As a cafe or coffee business owner, the relationship you develop with your local equipment service company cannot be undervalued.

We want to help the customers who have invested in correctly caring for their equipment. We don’t want to take on the liability of equipment that has been ignored until it can’t be or otherwise is not cared for properly. The other thing I’d say about this topic is that everyone wants service after 3 p.m. Some of the most talented coffee techs and technical service companies are small, one—to three-person operations that have families they enjoy seeing and spending time with from time to time.

Suppose you have a day that you are closed or a slow day that you are willing to close. This is the best time to schedule service. Maybe you have a Linea Mini or GS3 and are eager to make an espresso while maintenance is completed. Be willing to get creative with your product offerings or how you can maintain service while the tech is onsite during more “normal” hours to address your service needs quickly.

Do you have any specific tech or service tips for café owners and baristas during busy times of the year?

Most coffee businesses can predict these busy times of the year. Call your tech well before the season starts and have your maintenance cycle coincide with these seasons. For example, having a fresh 12-month PM executed in September or October before your busy holiday season can set your machine up for a smooth, emergency-free quarter.

It is not directly related to the espresso machine, but environmental considerations have a huge impact. Ambient dust, grease, and significant temperature changes can wreak havoc on grinders and espresso machines. Changing building air filters, servicing refrigeration, and other hood/vent/HVAC equipment before a busy season can also set your espresso machine up for a healthier season as it mitigates these particles and substances from affecting electronics and controls inside your espresso machine.

On a practical day-to-day level, ensure you are precise in your cleaning habits. After a busy period, you are backflushing your machine, purging steam wands, and cleaning steam tips. Flushing your drain tray and machine drain box with hot water is an easy and practical way to keep your machine running well, especially during busy seasons. Another healthy tech tip is to run around a liter or two of hot water out of the water spigot/americano jet each night. This will purge the steam boiler of concentrated TDS water, help introduce fresh water, and reduce sediment in the steam boiler. On the opening side, running about 500mL of water out of each group head before dial-in effectively brings fresh water into your coffee boiler while ensuring portafilters and baskets are up to machine temperature and ready for dial-in.

Reach Out

If you have any questions or would like to discuss preventative maintenance in more detail, please reach out to our technical support team at solutions.usa@lamarzocco.com or (206) 706-9104 x101 or visit us at https://lamarzoccousa.com/support/.

Visit Caliber Coffee’s website and follow them on Instagram.