When the Modbar debuted in 2013, it presented something no one had seen before: an undercounter espresso machine. And while the focus in the early days of Modbar was on reducing barriers between barista and customer, it was also a platform that had potential for showcasing the most innovative coffee technology that La Marzocco was working on. As exciting as it was to see pressure profiling integrated into a groundbreaking form factor, there was something even more subtle and revolutionary hidden inside the grouphead: a brand new temperature stability system. Every Modbar includes a dual PID temperature controller to manage both the grouphead and boiler temperatures, but to understand how it works and why the system is so revolutionary, first we need to talk about the challenges the Modbar faced.

Temperature Stability and the Saturated Grouphead in Espresso Machines

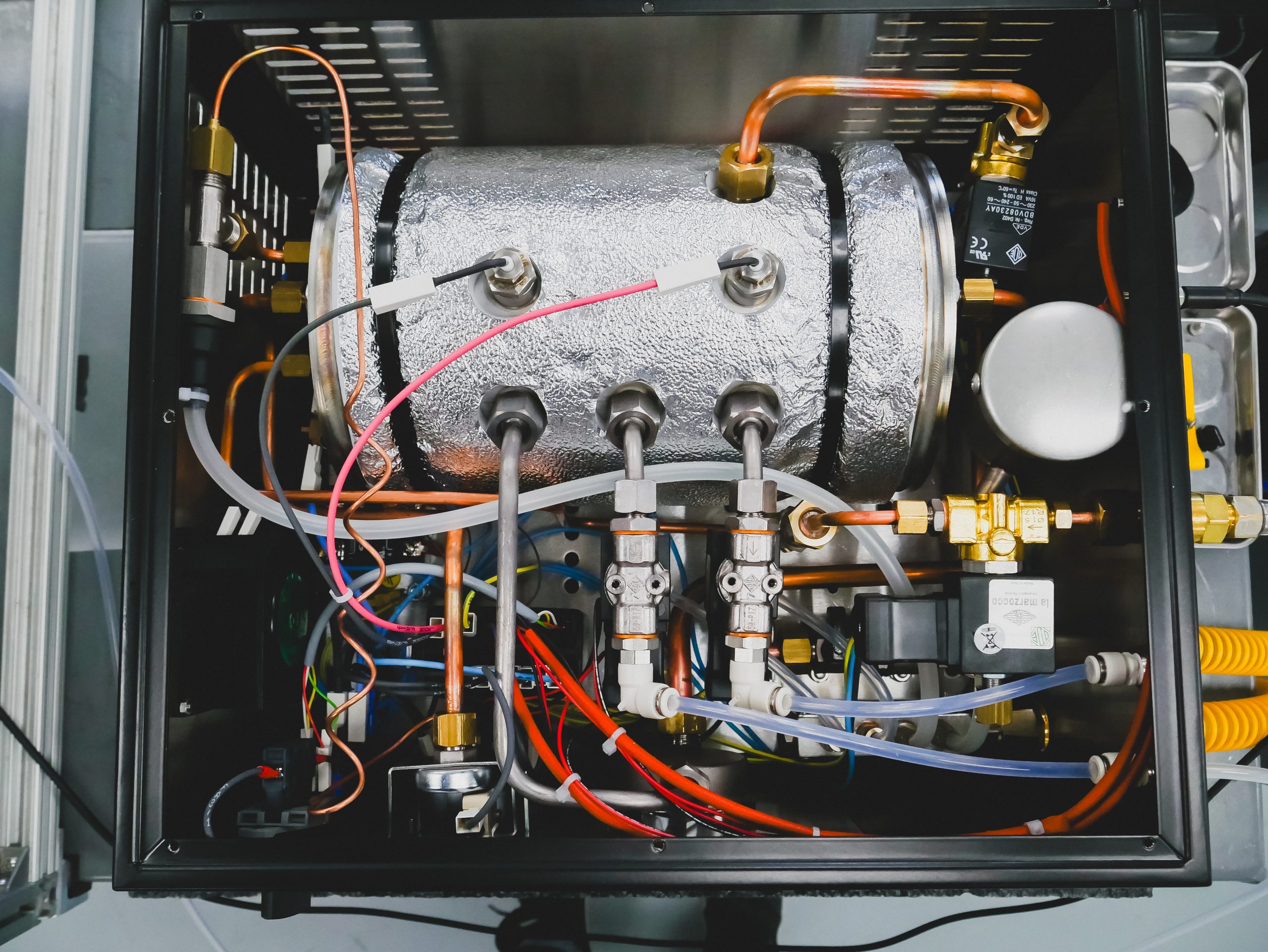

When La Marzocco debuted the GS in 1970, it was the first machine to feature dual boilers: one for espresso brewing, and one for steam. It also was the debut of the saturated grouphead. By attaching the espresso grouphead directly to the coffee boiler and allowing hot water to flow around the portafilter, the La Marzocco GS showcased a new style of temperature stability that other espresso machines couldn’t compete with. Now both the grouphead and portafilter would be stabilized at the same temperature as the espresso boiler, reducing the temperature difference between the water in the boiler and the temperature inside the portafilter when the shot was pulling. This also set the stage for the inclusion of PID controllers in espresso machines to achieve better temperature precision. When the Modbar’s design became integrated with La Marzocco’s manufacturing processes, it already included a PID controller for precision temperature control in the boiler. But the engineers ran into a tricky situation compared to other La Marzocco espresso machines: because of the placement of the undercounter boiler and the above counter espresso tap, it wouldn’t be possible to include a saturated grouphead.

Modbar: Designing the First Undercounter Espresso Machine

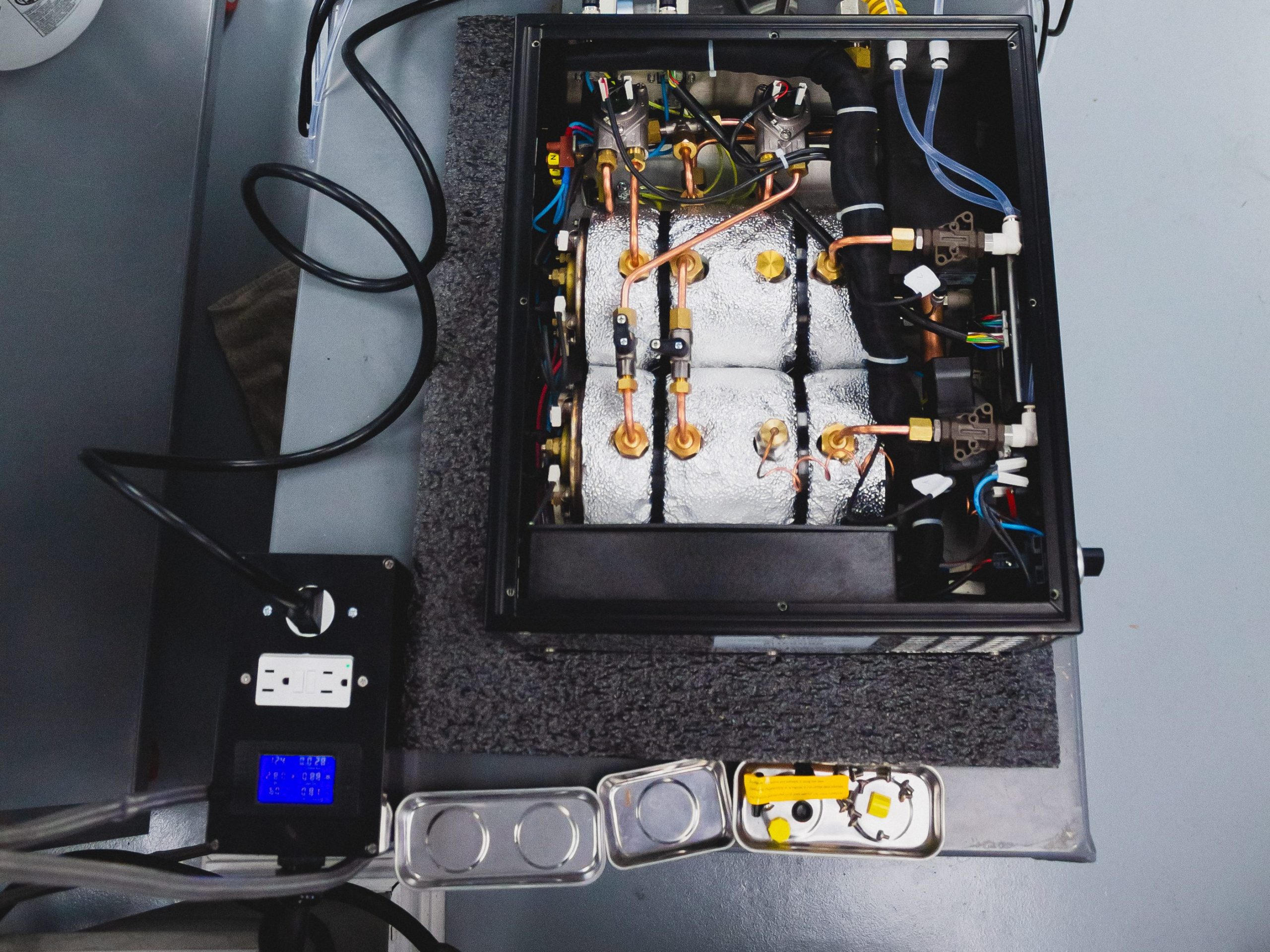

While most machines with a PID controller attached to the boiler can achieve a stable boiler temperature easily, simulating real-world cafe usage of an espresso machine is a different situation. The La Marzocco engineers had adopted the testing protocol for the World Coffee Events temperature stability standards, and they noticed that in initial tests, the Modbar wasn’t measuring up to other La Marzocco espresso machines. Because of the distance between the boiler and the espresso tap, the first 20% or so of an espresso shot was brewing around 2ºC cooler than the rest of the shot. When the machine was in heavy use, however, the engineers saw there was less discrepancy between the boiler temperature and brewing temperature. Since the testing protocol requires pulling shots at different intervals to simulate idle periods and busy periods in a cafe, it become clear that without a saturated grouphead, a new temperature stability system would be required.

Redefining Temperature Stability in Espresso Machines

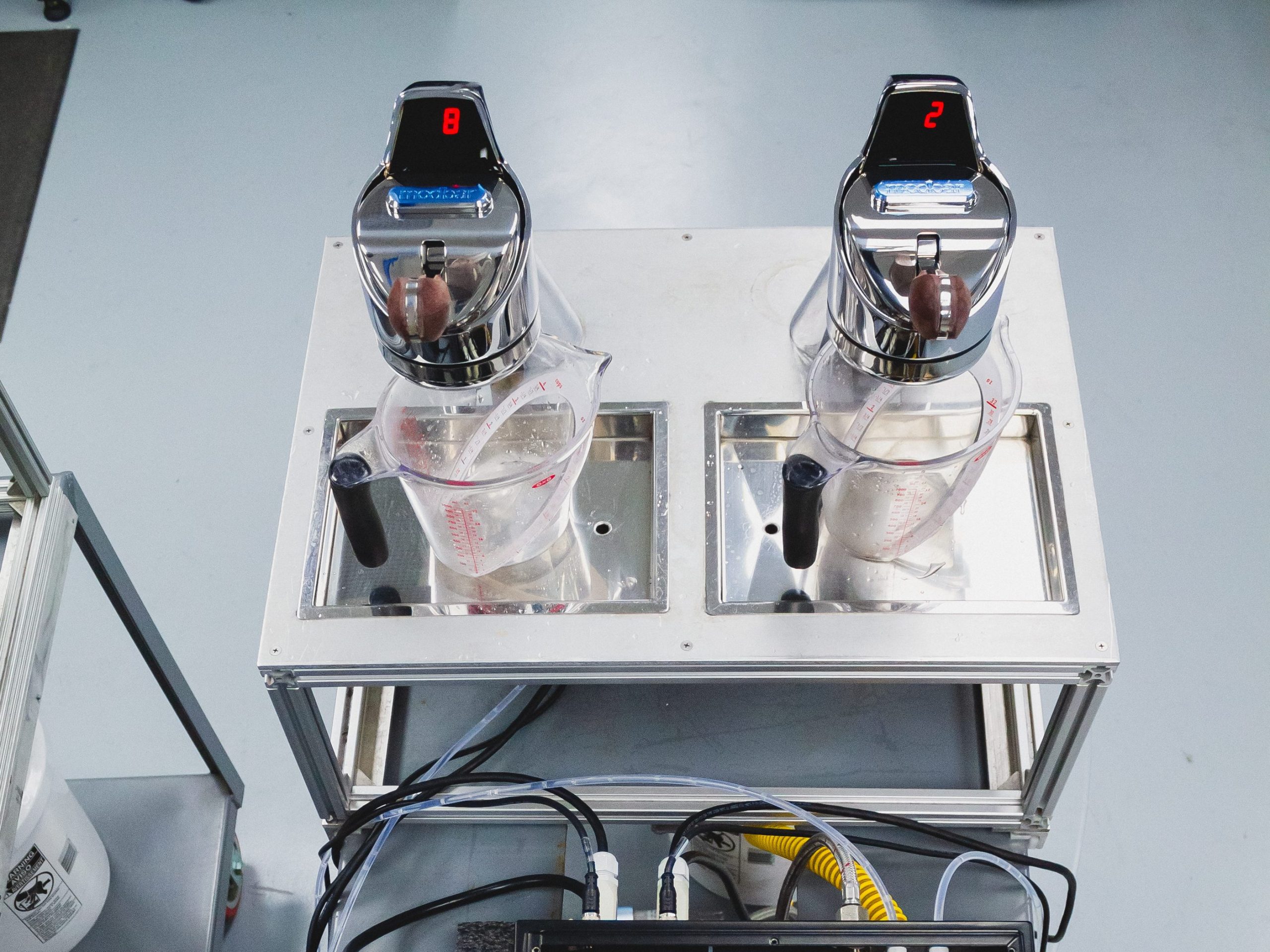

By recording hundreds of hours of temperature stability graphs between the boiler temperature, grouphead temperature, and simulated espresso temperature in a portafilter, the engineers were able to spot the issue. The metal of the espresso tap, as it sits exposed to the air, loses temperature when idle. As flowing hot water moves from the boiler up through the grouphead, the water from the boiler would transfer its heat efficiently to the metal of the espresso tap until it equalized with the temperature of the water. Circulating water is extremely efficient at transferring temperature—compare a circulating water bath wine chiller vs. placing a bottle of wine in the refrigerator—so as long as the espresso tap cooled down some between shots pulled, it would pull heat from the water passing through it.

The engineers deduced that a secondary heating system in the Modbar would be necessary to help offset this transfer of heat. But instead of creating a secondary boiler in the grouphead, they came up with an ingenuous plan: by heating the metal of the espresso tap directly, they could ensure that the water traveling through it would be able to maintain the exact temperature it was set to in the boiler. They then developed a spiral-shaped water line inside the espresso tap that maximizes surface area contact between the heated metal and the water as it flows through it. With a second PID system monitoring the temperature of the heated metal of the grouphead, it would now be able to efficiently transfer that precise heat into the water as it flows around the “brew screw” spiral water line much more efficiently than a straight water line. Now all they needed to do was figure out the best way to execute their system.

The process started first with fine-tuning the PID in the espresso boiler. By going through hundreds of hours of recorded data, the team discovered they could model the temperature fluctuations in the boiler more precisely than that of a standard espresso machine. Because the Modbar boiler is smaller than that of a two-group espresso machine, it experienced temperature fluctuations more frequently as cold water was drawn into the boiler to replace the hot water that went out. At the same time, the boiler was much more responsive to heating—that meant that the heating element could kick on full power to supercharge heating quicker before the PID would take over to prevent the boiler from overshooting the set temperature. With a fine-tuned PID in the boiler, it was then time to figure out how to best prime the espresso tap itself.

In this case, a simpler solution was better. Instead of rigging a communication system between the two PIDs, the Modbar team realized they could use the same temperature data to model simulated use in a cafe. The algorithm they developed from that data set could accurately predict the grouphead temperature based on time passed since the last shot. This allowed them to program the grouphead PID to adjust its set point temperature based on how much time had passed since the last shot was pulled. For example, if it had been longer than five minutes since the last shot was pulled, the grouphead PID would target a higher temperature set point compared to if the last shot had been pulled only 30 seconds ago. And since the two PID systems work independently of each other, both have a supreme degree of accuracy.

When set up together, the dual PID temperature stability system of the Modbar offers much higher precision and accuracy than most espresso machines available today, making it the perfect espresso solution for anyone looking for the best possible extraction.