The 3 way solenoid valve: the little-known part in your espresso machine that makes everything work.

Usually, when people describe espresso machines, they break down their features by talking about the number of group heads a machine has or how ergonomic the portafilters are to use.

Rarely do they talk about the solenoid valve, a small electric piece with outlet holes that directs and controls the flow of water.

The solenoid valve is the part on your espresso machine that makes everything happen — ok, maybe not everything, but its function is vital to the well-being of your machinery and makes pulling shots much safer and quicker than in times past.

Solenoid valves play an essential part in the modernization of machines and have helped push machine technology and espresso quality forward — and we think it’s important to understand exactly how they work.

where is the solenoid valve and what does it do?

In its simplest form, a solenoid valve controls the flow of water. When you’re using an espresso machine, it’s the reason water isn’t just running through your grouphead all the time but instead only flows when you’re pulling a shot or flushing the group.

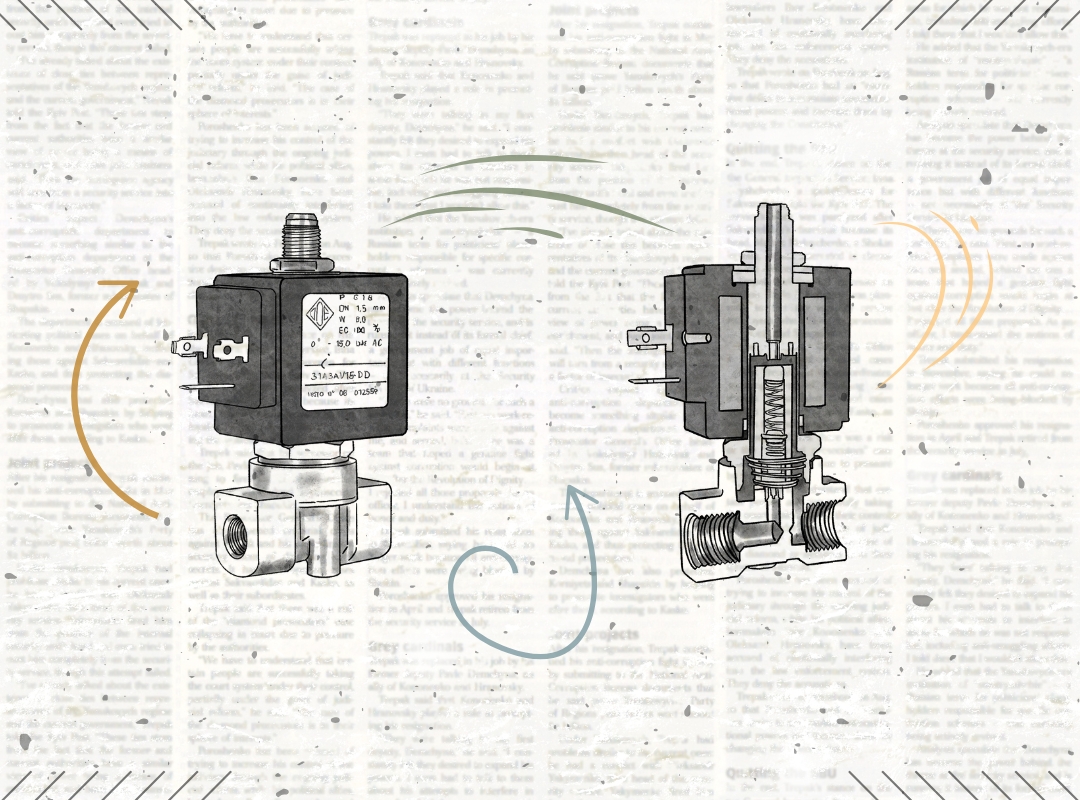

“It’s a valve driven by electricity that manages the flow of the water in the coffee machine,” said Riccardo Gatti, Research and Development Manager for La Marzocco. Solenoid valves look like tiny boxes (they house the solenoid, which is an electromagnet shaped into a coil) with small metal or plastic tubes attached (the valve). When the coil is activated, “it becomes magnetic and attaches to a plunger that opens and closes,” controlling the flow of water, said Gatti.

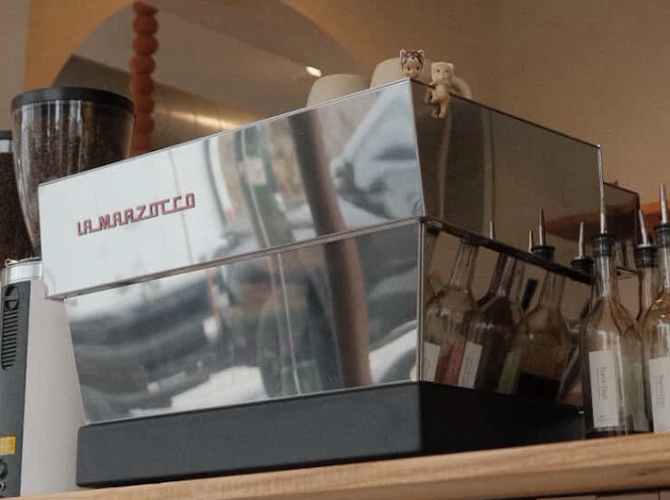

La Marzocco espresso machines have three-way valves that control the water flow between the group head and the boiler. Each group head of a machine has a three-way solenoid valve, and the valves can be found behind the back plate of your espresso machine.

More espresso machine parts: screens, gaskets, and baskets

When you start your espresso shot, water moves from the boiler to the group head via the solenoid valve. When the shot is done, the three-way valve then diverts water into the drip tray, which you can see if you lift the grate of your drip tray. Pull a shot: once the shot ends, you’ll see water exit a small tube called the discharge— that’s the three-way solenoid valve at work, removing water from the top of the group head and depressurizing it.

This is important because espresso uses pressure and water to extract flavor from coffee grounds. Once the shot is done, the three-way valve depressurizes the group, ensuring you can remove the portafilter both immediately and safely without water and grounds going everywhere.

If you’ve ever tried removing a portafilter from a machine without a three-way valve (for example, a machine that works with a pump, like a pulley machine), you’ve likely either had to wait a few moments to remove the portafilter or have felt the ricochet of the grouphead that’s still pressurized, which can pose a threat to baristas.

“Three-way valves remove all the water from the top of the coffee,” Gatti said. “The difference in pressure moves the water out from the basket, and then all the liquid on top of the coffee goes to the discharge drain.”

For busy cafes, being able to remove a portafilter immediately after pulling a shot is vital: imagine having to wait thirty seconds in between shots before you can prep and pull another shot. Three-way valves help make it possible for businesses to scale up and serve more customers quickly.

maintenance for your 3 way solenoid valve

Enrico Wurm, Field Test and Product Improvement Manager for La Marzocco, says that the solenoid valve is “one of the most important parts” of the machine and that keeping the valve clean through regular backflushing is vital to performance. “It must be cleaned so that the flow rate stays the same — you always want a consistent flow of water.”

He also points out that keeping the solenoid valve clean is vital for the pre-infusion phase of shot pulling. If the valve is clogged with debris and old coffee (which happens when you don’t regularly backflush and skip using detergent), that can slow down the water flow.

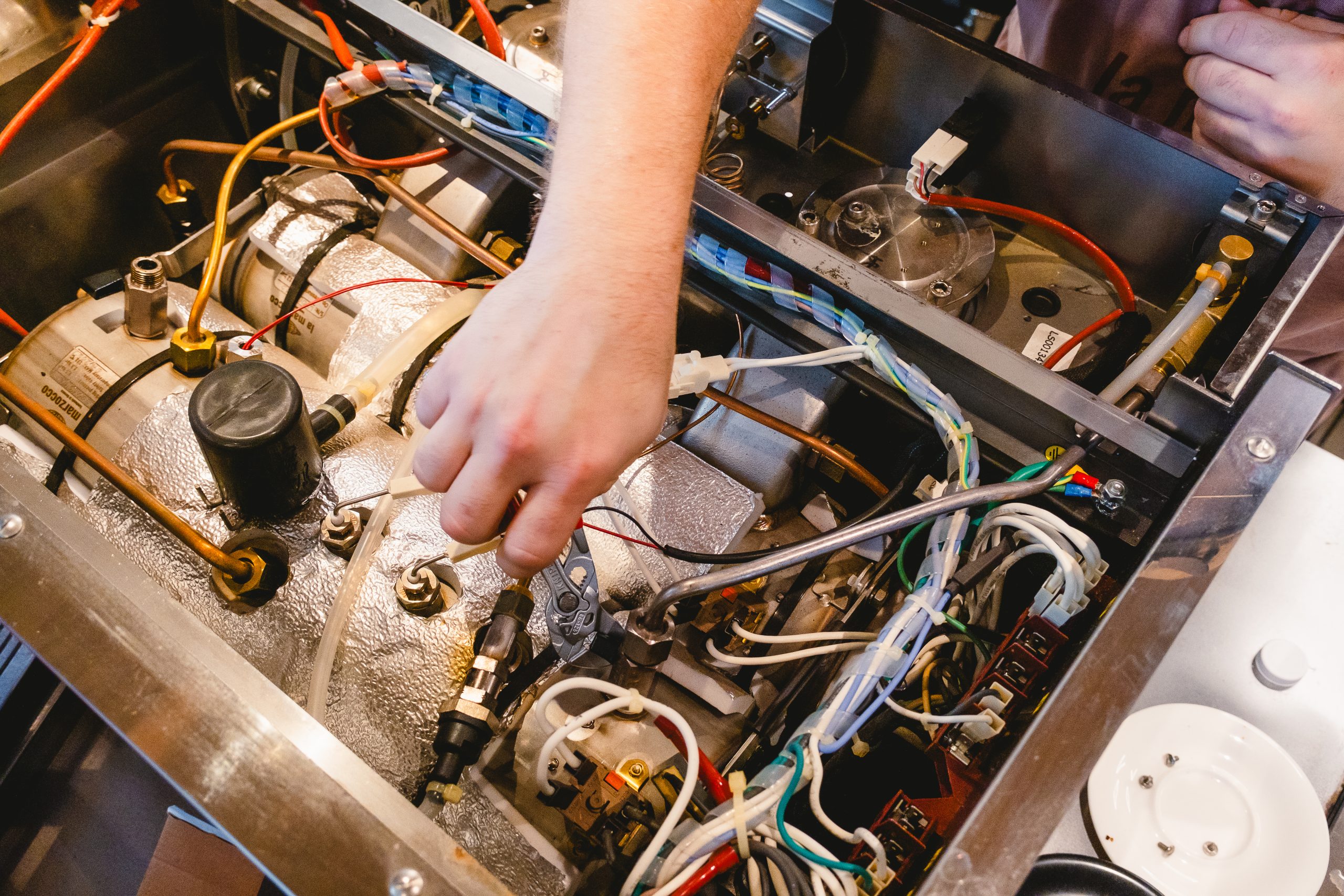

With how much care is put into the design of items like the flow restrictor, the dispersion screen, and even the special dispersion screen screw (with a hole in the screw to allow water to flow), it’s important that the solenoid valve functions properly to allow water to and an espresso puck correctly.

Automatic espresso machines: a brief history of volumetrics in specialty coffee

Solenoid valves aren’t usually replaced or messed with as part of a technician’s regular machine maintenance, but there are ways to know if it’s on the fritz. If you notice your grouphead leaking water when you’re not pulling shots, that usually indicates that the solenoid valve isn’t closing completely. If you start a shot and no water comes out, that usually indicates the electrical part of the solenoid valve is broken (it’s not engaging with the plunger to allow water flow).

Both issues usually mean the solenoid valve needs to be replaced, but because each group head has its own valve, one being broken shouldn’t impact the rest of the machine. Wurm recommends replacing the solenoid valve every 1,000,000 uses, but because solenoid valves involve electricity and pressure, they should only be managed under the advisement of an experienced technician.

The solenoid valve is responsible for critical mechanisms in your espresso machine, but it’s often overlooked because it’s out of sight. However, understanding how it works can tell you a lot about your machine and help make a complex piece of equipment easier to navigate.